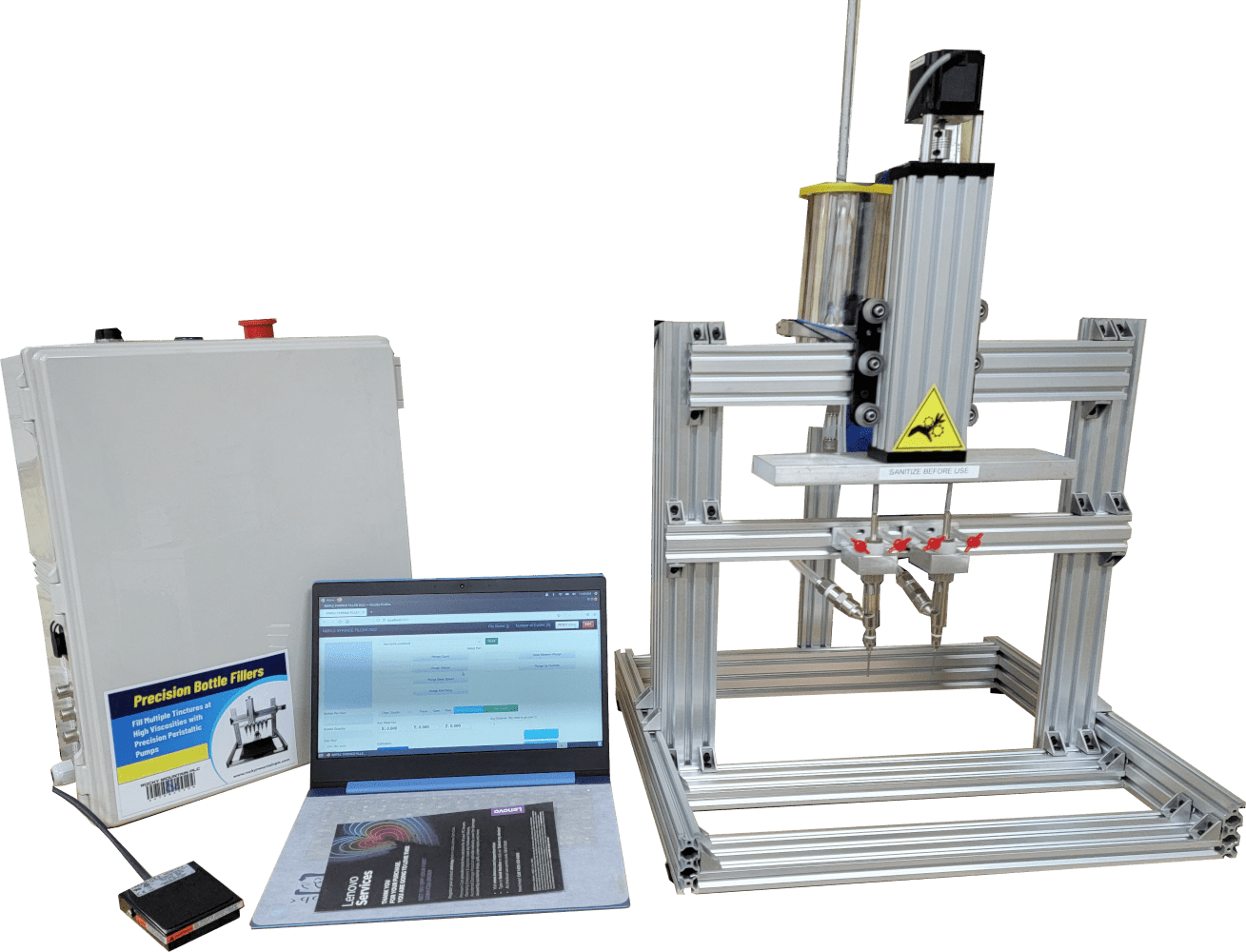

Organizations today want ways that help them keep things smooth and lower mistakes during production. A steady process brings trust and reliability to the different tasks that need careful work. Solutions that make dispensing easier are also important. Using an automatic vape cartridge filling machine from the start can make things better in a big way. It helps teams reach their goals and check every step as things move along. When businesses use these machines, they keep big standards and, at the same time, waste less by cutting down on doing things over.

Efficiency Gains

Speeds up the work by being able to pour several units at once using just one setup

- Helps the operators feel less tired, making the process safe for everyone.

- Manages steady output, so there are fewer risks for all the production runs.

- Keeps the flow rate the same and helps with guessing how much of each batch is needed.

- Works together with helper devices, which let users keep track of how things are going.

- Need for watching over the system is low, as automation helps keep things steady.

- Cuts extra waiting down, making sure products get to customers on time.

Error Control

Stops manual mistakes by letting users see every step of the process.

- Keeps waste low so that the team saves materials during the whole pouring process.

- Keeps the same amount in each portion, so results match from the first batch.

- Makes it easier to watch the process by giving clear numbers so the team can decide easily.

- Sets up results that build trust with everyone who checks how things are going.

- Makes sure every output stays the same, no matter what hour it is.

- Gives checking while it works in real time, so those who are new don’t make simple mistakes.

Lasting Compliance

A strong system is there to prevent mistakes that may come up, so regular problems do not happen. By working this way, the company builds trust with people and they feel safe to choose it. It also keeps day-to-day risks low. Using smart tools like automatic vape cartridge filling machine opens the door for us to find new chances. It also lets us spot problems early. This helps every step work smoothly. A hands-on method gives good results you can count on and keeps things running right, so most workers feel safe the whole time. A steady setup helps people feel sure about the work and keeps the company moving forward.